Overview

In the manufacturing industry, following the globalization of the supply chain, there has been a demand for a revolution in production and services using IoT*. With that backdrop, we are working on the automation of systems, focusing mainly on Programmable Logic Controllers (PLC), which control various plant facility devices, and IPCs (industrial PCs), which are responsible for gathering data from plant facility devices and communicating with servers and other higher level information systems* IoT: Internet of Thing

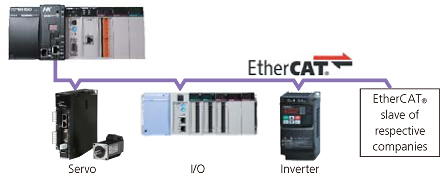

EtherCAT® Motion Control

- Controls multiple axes and I/O using EtherCAT®

(Various EtherCAT® slave devices such as Hitachi AC Servo ADV series) - Supports function blocks for PLC open compliant motion control

Supports programming languages compatible with IEC61131-3 international standards

Supports data login using SD memory

Sensor and actuator control

(Various sensors and actuators including Hitachi inverters)

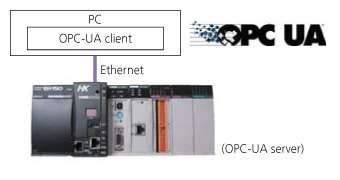

OPC-UA for communication with higher level information systems

ERP linkage, MES connection, SCADA system connection, etc.

Supports information communications

Ethernet (TCP/IP), IP communications, web support, etc.

Connection with various control equipment and HMI

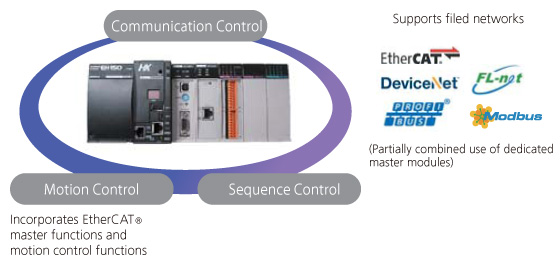

Field network support

(Partially combined use with dedicated master modules)

Features

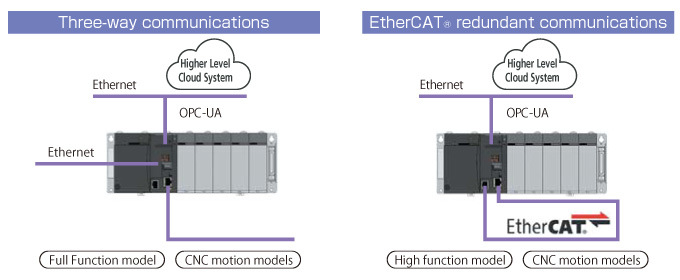

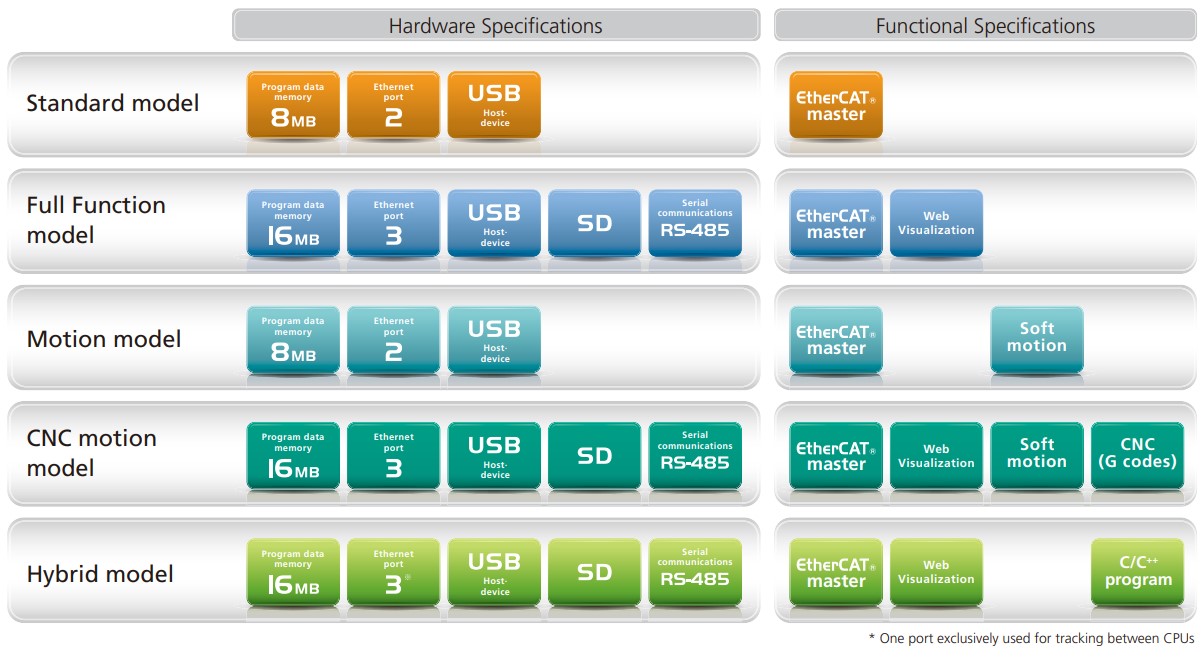

3 Ethernet ports are standard (Full function model, CNC motion model)

- Standard model and Motion model are 2 Ethernet ports

Integrates core control and communications of automated machines and production facilities

OPC-UA has soft interface standards between industrial equipment and the OPC-UA server function is standard (for all models)

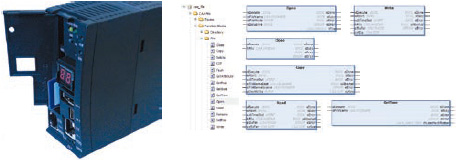

Supporting programming languages compatible with IEC61131-3 international standards (for all models)

LD (Ladder Logic Diagram)

ST (Structured Text)

IL (Instruction List)

SFC (Sequential Function Chart)

FBD (Function Block Diagram)

CPU modules that can be selected to cater to your applications

SD card for large capacity data logging (Full function model, CNC motion model)

The SD card can be mounted on the CPU model, which makes it possible to easily log the data generated on the site (Function blocks for file access are available.)

EtherCAT® master & SoftMotion (The EtherCAT® master function is incorporated into all models; the SoftMotion function is incorporated into the Motion model and CNC motion model.)

The EtherCAT® master function and motion control function are incorporated into the LAN port of the CPU module. A combined use of an EtherCAT® slave beside servo is possible (inverters, IO terminals, and so on.)

Supporting function blocks for PLC open compliant motion control (Motion model, CNC motion model)

From PTP positioning with a single axis and interpolation control and synchronization control of electronic cam to speed control and torque control, various functions are possible through the combined use of FBs.

Reduction in maintenance costs (all models)

No fan

The mechanical mechanism for consumables is not adopted for CPU modules.

No Battery

Nonvolatile memory is adopted for program memory and data memory. Machine production records are stored without batteries. Even if power is turned off due to the unexpected outage, important programs and data will be protected.

- To maintain calendar and clock data, batteries are required.

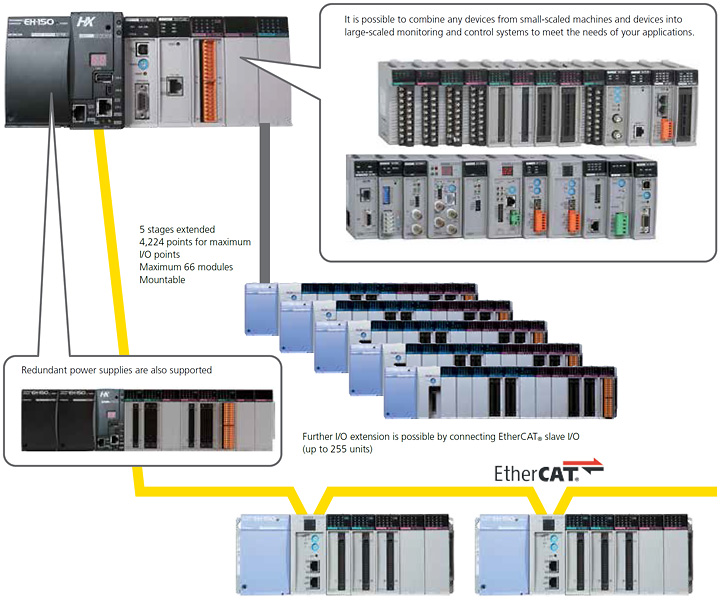

Flexibly extendable structure by adopting plug-in type modules

Functions can be extended using various modules from the reliable and proven EH-150/EHV series (digital input and output, analog input and output, and various function modules.)

Protecting machine production and information

Unauthorized access will be prevented and your machine information will be protected when a connection is made to networks.

Prevention of unauthorized external access

- Prevention and detection of unauthorized external packets

- Prevention of unauthorized remote log-ins

- Prevention of the provision of information and functions to attackers

Prevention of unauthorized external access

- Login authentication, user and group management, access

Creating a library for dedicated functions (non-display)

Online user registration

Access rights settings

User management

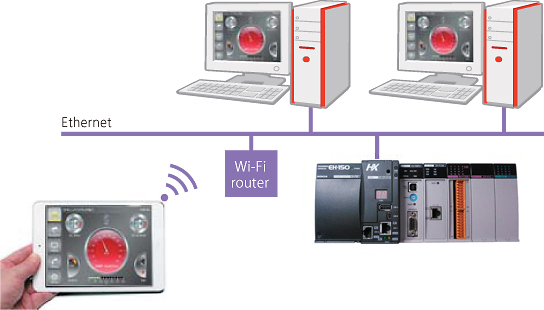

Monitoring with a web browser (Web Visualization)

t is possible to have access to the web server of the controller with a generic web browser without preparing the dedicated HMI and a monitor. This reduces dedicated terminals for monitoring and creates burdens on the workers.

- Comes standard in the web server

- No need for dedicated HMI

- Monitoring with a generic web browser

- Remote maintenance, diagnosis, and control

Specifications

Industrial Controller : HX Series : Functional Specifications : Hitachi Industrial Equipment Systems

| Model | Specifications | ||||

|---|---|---|---|---|---|

| Standard model | Full Function model | Motion model | CNC motion model | ||

| Item | HX-CP1S08 | HX-CP1H16 | HX-CP1S08M | HX-CP1H16M | |

| Program capacity | 8MB | 16MB | 8MB | 16MB | |

| Data memory(non-retaining) | 8MB | 16MB | 8MB | 16MB | |

| Data memory(retain when outage occurs) | 0.5MB | ||||

| Number of extension stages | 5 | ||||

| Extended cable | 0.5m, 1m, 2m | ||||

| Extension distance | Maximum 2m between bases, maximum 8m in total expansion | ||||

| Number of base mounted modules | Maximum 11 units(excluding power supply modules and CPU modules) | ||||

| I/O points (when using a 64-point unit) | 4,224 points | ||||

| Command processing speed | Bit operations | 1.0ns | |||

| Double-precision real- number arithmetic operations | 6.6ns | ||||

| Programming language | Five languages in conformance with IEC61131-3 standards (LD/FBD/SFC/IL/ST) + CFC (Continuous Function Chart) | ||||

| I/O processing method | Refresh processing | ||||

| Supported functions | OPC-UA | ✔ | ✔ | ✔ | ✔ |

| WebVisualization *1 | - | ✔ | - | ✔ | |

| NTP(Network Time Protocol) | ✔ | ✔ | ✔ | ✔ | |

| FTP(server client) | ✔ | ✔ | ✔ | ✔ | |

| EtherCAT® master | ✔ | ✔ | ✔ | ✔ | |

| (EtherCAT® communication cycle) | 1ms∼ | ||||

| Modbus-TCP client | ✔ | ✔ | ✔ | ✔ | |

| Modbus-TCP server | ✔ | ✔ | ✔ | ✔ | |

| Modbus-RTU master | - | ✔ | - | ✔ | |

| Modbus-RTU slave | - | ✔ | - | ✔ | |

| SoftMotion | - | - | ✔ | ✔ | |

| CPU redundancy | - | - | - | - | |

| Standard input and output interface | Ethernet port | ✔(2 ports) | ✔(3 ports) | ✔(2 ports) | ✔(3 ports) |

| SD card slot | - | ✔ | - | ✔ | |

| RS-485 serial | - | ✔ | - | ✔ | |

| USB host(USB memory) | ✔ | ✔ | ✔ | ✔ | |

| USB device(PC connection) | ✔ | ✔ | ✔ | ✔ | |

| Calendar clock | 60 second difference in a month with built-in RTC and 25 degrees in ambient temperature | ||||

| Battery(sold separately) *2 | HX-BAT(for clock IC) | ||||

| Maintenance function | Self diagnosis (abnormalities of microcomputers, watch dog timers, memory, batteries, and others) | ||||

- Simple SCADA function

- Batteries are required to retain calendar clock data. In the case of synchronization with NTP server time, and in order to retain user programs and data memory with outage retaining attributes, batteries are not required.

| Items | Specifications | |

|---|---|---|

| Ethernet port specifications | Physical layer | 10BASE-T, 100BASE-TX |

| Transmission mode | AUTO, 100 Mbps full duplex, 100 Mbps half duplex, 10 Mbps full duplex, 10 Mbps half duplex | |

| Modulation method | Base band | |

| Topology | Star type | |

| Transmission media | Twist pair cable with shields (STP), category 5/5e or higher | |

| Transmission distance | 100m | |

| Supports function | EtherCAT6® master, Modbus-TCP client, Modbus-TCP server, CODESYS Gateway*1, network variables, TCP/IP, UDP/IP, NTP, FTP server, http*2 |

|

| USB host | Standard | USB 2.0 High Speed(480 Mbps) |

| Connector | A type | |

| File system | FAT32 | |

| Maximum capacity | 32GB | |

| Maximum capacity per file | 2GB | |

| Bus power source capacity | 500mA | |

| Transmission distance | 5m | |

| Supported function | Program transfer, file system | |

| USB device | Standard | USB 2.0 High Speed(480 Mbps) |

| Connector | mini-B type | |

| Transmission distance | 5m | |

| Supports function | CODESYS gateway(exclusively for integrated development environment HX-CODESYS connection) | |

| Serial*3 | Standard | RS-485 |

| Transmission speed | 4,800 / 9,600 /19.2k / 38.4k / 57.6k / 115.2k / 230k bps | |

| Communication method | 2-wire type, half duplex | |

| Synchronous method | Start-stop synchronous communication | |

| Maximum message length | 256 bytes(Modbus-RTU) | |

| Connector | Phoenix(5pin) MC1, 5/5-G-3, 5-RN(AU) | |

| Terminal resistor | 120Ω(attached) | |

| Transmission distance | 1,200m | |

| Error check | Vertical parity check, overrun check, framing check | |

| Supports function | Modbus-RTU mater, Modbus-RTU slave, generic communications | |

| SD card*3 | Standard | SD(Maximum 2GB), SDHC(2 to 32GB) |

| Bus interface | Normal speed, high speed | |

| Bus speed | Maximum 25 MB/s | |

| Specification version | 2.00 | |

| File system | FAT32 | |

| Maximum capacity | 32GB | |

| Maximum capacity per file | 4GB | |

| Supports function | File system | |

- Gateway is a communication function with the integrated development environment(CODESYS).

- HX-CP1S08, CP1S08M does not support the http function.

- Serial ports, SD memory are not available for HX-CP1S08, CP1S08M.

Industrial Controller : HX Series : EtherCAT® Master Specifications

| Items | Specifications |

|---|---|

| Communication protocol | EtherCAT® dedicated protocol(CoE) |

| Support service | CoE(process data, SDO communications) |

| Synchronous communications(DC) | Supported |

| Physical layer | 100BASE-TX |

| Modulation method | Base band |

| Transmission speed | 100Mbit/s(100BASE-TX) |

| Duplex mode | Full duplex/Auto(automatic) |

| Topology | Daisy chain, branch wires |

| Transmission media | Twist pair cable with shields, category 5 or higher |

| Transmission distance | Within 100m in distance between nodes(IEEE802.3) |

| Maximum number of slaves | 255 |

| Maximum process data size | Input 5,736 bytes/Output 5,736 bytes |

| Maximum size per slave | Input 1,434 bytes/Output 1,434 bytes |

| Maximum message size | 2,048 bytes |

| Communication cycle*1 | About 1ms(motion control 1ms/4axes, 2ms/8axes, 4ms/16axes) |

| Process data communications |

|

| SDO communications | CoE

|

| Configuration |

|

| RAS function |

|

| Slave information |

|

| Mailbox |

|

- Ethernet ports should not be used for purposes other than the EtherCAT® master function when using the EtherCAT® master function.

- The communication cycle must be increased depending on the number of slave devices to be connected.

Inquiries

Contact us for inquiries about our products, quotations, and catalog downloads.