Industry trends

With the working population in decline, many industries have recently begun to see labor shortages as a problem. In the pharmaceutical manufacturing industry, even as the market is growing with the expanding elderly population, increased demand for regenerative medicine, and other trends, companies must comply with GMP and other strict laws and regulations. This makes it essential to increase productivity to maintain quality and meet demand, despite a limited workforce.

Meanwhile, all industries face a common challenge in environmental issues. As climate change intensifies and demands that corporations fulfill their responsibilities increase, business partners, consumers and other stakeholders are placing increasing importance on environmental considerations. Production sites are expected to swiftly implement energy-saving and decarbonization measures, alongside the needed productivity improvements.

Solutions

Here, we show how Hitachi Industrial Equipment Systems can help meet these challenges, using examples of common issues in the pharmaceutical and biotechnological industries.

Maintenance and equipment monitoring services for safety

Ensuring safety is the top priority at pharmaceutical manufacturing sites. Of course, problems must be prevented before they occur, and if they do arise, prompt action is required. If a power failure occurs, it may take several days to clean up the facility. Preventive maintenance also plays a vital role in maintaining productivity. Given the complexity of the manufacturing processes, however, the possibility of human error remains a constant concern in environments that are difficult to efficiently monitor.

With its comprehensive service framework, Hitachi Industrial Equipment Systems can help companies ensure on-site safety. With timely equipment maintenance, we optimize maintenance costs and operating costs. If a problem does occur, we provide a rapid on-site response with our skilled and reliable staff. Introducing equipment monitoring services to track product operations in real time via remote monitoring reduces the inspection burden and helps our customers reduce long-term costs. A 24-hour low-voltage insulation monitoring system can also be installed to more effectively prevent power outages and fires without the need for large-scale construction work.

Common challenges

- Optimizing equipment maintenance costs

- Strengthening preventive maintenance of power outages and fires

- Streamlining of safety confirmation operations

Example solutions

- Maintenance services for efficient inspections and malfunction detection

- Setting up low-voltage insulation monitoring systems simply by adding ZCTs

- Numerous products compatible with equipment monitoring services are available

Related products and solutions

LCM services

LCM services optimize production sites. They support the entire process from equipment introduction to maintenance and energy-saving activities.

Hitachi Connected Service

An IoT-enabled equipment monitoring service that helps reduce downtime by quickly detecting abnormalities.

i-moni low-voltage insulation monitoring system

A 24-hour low-voltage insulation monitoring system. i-moni prevents accidents such as electrical fires and sudden power outages.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

It also helps reduce energy consumption and is environmentally friendly.

The entire industry must consider the environment. This requires initiatives that increase energy efficiency, reduce water and power consumption, achieve decarbonization and carbon neutrality at production sites.

Hitachi Industrial Equipment Systems offers an extensive range of energy-saving high efficiency products that help production facilities save energy. For instance, we offer air compressors and green products including eco-friendly products that help to reduce the environmental impact. We also balance the stable supply of products with a reduced environmental footprint by instituting a recurring business model that supports the entire process from use to maintenance, replacement and recycling.

Common challenges

- Minimizing factory power consumption

- Tackling initiatives for reducing factory CO2 emissions

- Reducing environmental pollution risks

Example solutions

- Proposing optimal solutions from among many energy-saving products

- Building an efficient system for reusing waste heat from air compressors

- Using transformers with soybean-derived insulation oil to reduce pollution risks

Related products and solutions

Air compressors

Available in series ranging from small to large, we offer optimal air compressor options with the right quantity, voltage and for the right place.

Transformers

Our transformers help stabilize power supply while improving energy efficiency and disaster preparedness. We have an extensive lineup of transformers, ranging from high voltage to extra-high voltage transformers.

SANFEMS neo

It is a comprehensive factory energy monitoring system. It examines how energy is used and rationalizes and optimizes equipment operations.

Green products

We have a broad range of green products, including energy-saving, high efficiency and eco-friendly options.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

Providing products and solutions that meet rigorous standards

The pharmaceutical manufacturing industry must comply with many different laws and regulations, such as GMP, while also meeting numerous validation requirements. For example, there are strict standards regarding motor noise and vibration. The recent increase in high-mix, small-lot production has brought concerns about problems such as the inevitable increase in vibration when production is running at full speed. The industry must meet the standards while responding to the needs of the market.

Hitachi Industrial Equipment Systems is helping to meet healthcare needs with its broad range of oil-free compressors, which are almost an essential item in pharmaceutical factories. Noiseless, highly compact products can be installed in laboratories and other locations where space is limited. We have also been focusing on low-vibration motors to ensure compliance with standards. In addition, we provide entry and exit control systems that enable the restrictions and recordkeeping needed to ensure compliance with GMP, other laws and regulations.

Common challenges

- Oil-free compressors tailored to specific applications

- Motors with vibrations at or below set standards

- Access restriction and recordkeeping to comply with GMP

Example solutions

- A lineup of products compatible with a broad range of electrical systems, from 0.2 to 780 kW

- Low-vibration and customized motors

- Entry/exit control systems linked to ID cards

Related products and solutions

Air compressors

Available in series ranging from small to large, we offer optimal air compressor options with the right quantity, voltage and for the right place.

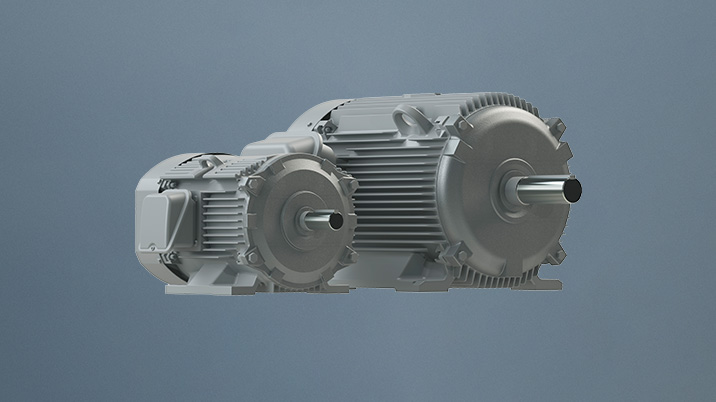

Motors

As we continue to expand our high-efficiency energy-saving product lineup, our motors are helping to reduce power consumption and CO2 emissions.

Entry/exit control systems for pharmaceutical facilities

These systems restrict entry and keep a record of people entering and exiting facilities to supplement manufacturing records. They facilitate compliance with GMP, other laws and regulations.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

Functions specifically designed to reduce worksite challenges

As demand for pharmaceutical products increases, many companies are facing the challenge of increasing productivity. Problems include quality inconsistencies among workers and the significant time and effort needed to maintain equipment to keep operations running. Pharmaceutical settings require precise operations and the human resources available to do these tasks are often limited. Meeting demand amid the labor shortage requires minimizing workloads and building systems that can be operated by non-specialists.

Hitachi Industrial Equipment Systems’ products are equipped with many different functions to reduce worksite challenges, such as the automation of maintenance that had been performed manually in the past and adjusting objects to a height appropriate for the engineer. In addition to achieving increased efficiency, these products help build a safe system that prevents workers from causing accidents or making mistakes due to excessive workloads.

Common challenges

- The quality of the print head cleaning varies depending on the worker

- Quick-drying inks increase the burden on workers in regular circulatory operations

- The opening of the BSC needs to be adjusted to the engineer's height

Example solutions

- Inkjet printers with automatic cleaning functions

- Automated regular circulatory operations using automatic operation when SCS is suspended

- BSCs with openings whose heights can be adjusted to 200 or 250 mm

Related products and solutions

Inkjet printer for industrial applications

The printer's functionality enables it to fulfill many different printing needs, and it has become easier to install. Usability and maintainability have also been improved.

Biological safety cabinets (BSCs)

Ensures worker safety and minimizes contamination. The height of the opening of the BSC can be adjusted to 200 and 250 mm.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

The expertise of the Hitachi Group is leveraged in consulting activities

The needs of production sites are complex. For example, companies want to keep their equipment introduction and maintenance costs low, but they want to improve their equipment. Measures to save energy and connect with local facilities must also be considered. Comprehensive system optimization requires expertise in both the IoT and equipment operations.

Hitachi Industrial Equipment Systems combines high-quality products with digital solutions to propose solutions tailored to the customer’s needs. This ability leverages the broad expertise and experience accumulated by the Hitachi Group. The Group’s comprehensive strengths enable it to offer new ideas to address even the toughest challenges. For example, we propose maintenance plans that balance stable operation with the optimization of costs and efficient systems using operation data. We can also provide support for addressing environmental issues, such as the need to save energy and recycle products throughout factories. With a one-stop solution, we handle the entire process from the introduction of products to system development, maintenance and environmental measures. We partner with our customers to create new value.

Common challenges

- Problems are so wide-ranging that it is hard to know where to begin

- Creating a budget for investing in and maintaining equipment is difficult

- Managing all equipment in-house is difficult

Example solutions

- Providing consulting services on the optimal use of equipment, based on a holistic view of the production site

- Additionally considering equipment leases and subscription services when discussing plans

- Analyzing data to look for telltale signs of wear and proposing preemptive maintenance

Related products and solutions

LCM services

LCM services optimize production sites. They support the entire process from equipment introduction to maintenance and energy-saving activities.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

Inquiries

Contact us for inquiries about our products and quotations.