Industry trends

Digitalization is rapidly transforming nearly every industry, encompassing technologies such as generative AI, vehicle electrification, and IoT-enabled appliances. Data centers are part of the digital infrastructure that supports the development of these technologies. As digitalization accelerates, the shortage of skilled engineers is becoming increasingly critical. Technological innovation requires increasingly large-scale, complex, and reliable equipment. There is an urgent need to boost productivity to meet needs with limited workforces.

Environmental issues are another major challenge. Power consumption continues to increase in step with information processing volumes and data traffic, triggering concerns about serious power shortages in the future. A fundamental overhaul of the energy infrastructure may be necessary, but data centers will also need to institute energy-saving measures and reduce GHG emissions. As climate change intensifies and the demands of corporate social responsibility increase, business customers, consumers and other stakeholders are placing greater weight on environmental considerations. Existing equipment may need to be improved to meet green imperatives.

Solutions

Below, we show what Hitachi Industrial Equipment Systems can do in the field of data centers, using problems common to the industry as examples

Solutions for streamlining security measures

Security measures are a necessary part of data center operations, as downtime can potentially result in enormous losses. Data center security systems must ensure high availability and redundancy. To ensure stable operations, equipment needs to be inspected regularly and security operations must incorporate professional knowledge. In this respect, the aging workforce and labor shortages are raising concerns about the future. and the labor shortage is becoming more acute.

Hitachi Industrial Equipment Systems provides diverse solutions to stabilize on-site operations and enhance productivity. For example, our low-voltage insulation monitoring system is able to identify signs that the insulation protecting electric circuits and other equipment such as uninterruptable power supplies (UPSs) is deteriorating. Our transformers include a built-in protection circuit to control power surges that may cause circuit breakers to trip. Our equipment monitoring service allows users to watch, on a real-time basis, how their equipment is working. We customize the devices to be introduced in accordance with customers’ equipment and requests, and support the streamlining of security operations and achievement of zero downtime.

Common challenges

- Implement preventive measures and conduct maintenance before a power outage occurs

- Take action to prevent power surges affecting transformers are needed to prevent downtime

- Streamline monitoring operations

Example solutions

- Low-voltage insulation monitoring systems for monitoring UPSs and electric circuits

- Transformers with built-in protection circuits to control power surges that may cause circuit breakers to trip

- Systems capable of remotely monitoring equipment operations

Related products and solutions

Hitachi Connected Service

An IoT-enabled equipment monitoring service that helps reduce downtime by quickly detecting abnormalities.

i-moni low-voltage insulation monitoring system

A 24-hour low-voltage insulation monitoring system. i-moni prevents accidents such as electrical fires and sudden power outages.

Molded transformers with built-in protection circuits

Built-in protection circuits help control power surges that may cause circuit breakers to trip. This contributes to the stable operation of large-scale data centers.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

The expertise of the Hitachi Group is leveraged in consulting activities

Numerous constraints should be considered when designing a data center, such as location conditions, load characteristics and operational conditions. Even the process of installing equipment in data centers is complicated and time consuming. Environmental surveys must be completed. Companies need to interact with government offices, choose the devices that will be used and undertake many other tasks. This is why choosing a partner is so important.

Based on the Hitachi Group's technologies and experience, Hitachi Industrial Equipment Systems supports the operation of customers' data centers from the planning stage to maintenance. These plans are achieved using highly reliably energy-saving products. Furthermore, equipment monitoring and other services contributes to the stable operation of data centers and improved productivity. We can also provide environmental support, for instance by proposing energy optimization measures and the recycling of products. Providing a one-stop solution for everything from the planning of equipment to the introduction of products, system construction, maintenance and energy-saving measures maximizes customers’ productivity and increases the environmental friendliness of worksites.

Common challenges

- Planning is challenging due to the complexity of site conditions and operational requirements

- There is a need for a trusted partner with a proven track record to be involved from the design stage

Example solutions

- Flexibly adjust measures to the location of the office, load characteristics, operational conditions and other considerations

- Utilize the Hitachi Group's design knowledge

Related products and solutions

Substation and power distribution systems

We propose reliable plans in accordance with location conditions, load characteristics, operational conditions and other considerations. The support we provide encompasses the entire process up to construction.

LCM services

They optimize production sites. The services support the entire process from the introduction of equipment to maintenance and energy-saving activities.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

Reliable and energy-efficient products

The primary environmental measure that data centers are expected to implement is the increase in their energy efficiency. Power consumption continues to rise as equipment becomes more sophisticated. A great deal of energy is used to cool systems to prevent heat-induced failures. The shift to energy-efficient equipment has become a key priority, both to protect the environment and to reduce running costs.

Hitachi Industrial Equipment Systems offers a wide array of products that balance reliability with energy savings. Going beyond the installation of a product, we achieve both a stable supply of products and a reduced environmental impact, and help our customers introduce initiatives for the environmental through our recurring business model in which we support the entire process from use, maintenance, replacement and recycling. *

- Recycling of some products is currently under way

Common challenges

- Given the complexity of conditions, it is difficult to create a plan

- A need to involvement of a partner with a proven track record from the design stage

Example solutions

- High-performance cooling pumps with proven track records

- Motors and transformers with high energy-efficient motors and transformers

Related products and solutions

Pumps

Our pumps support the plumbing of diverse facilities such as factories, buildings and condominiums. These products are designed to save energy and other resources while reducing the need for maintenance.

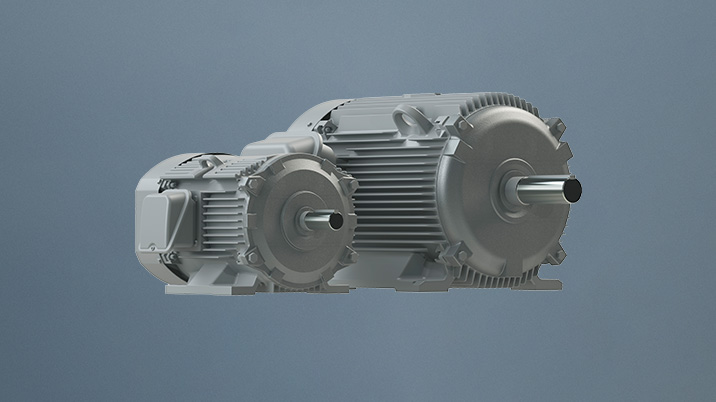

Motors

Thanks to our ongoing pursuit of a high-efficiency energy-saving product lineup, our motors help reduce power consumption and CO2 emissions.

Inverters

We have a wide range of products, such as a series of small, easy-to-operate smart-control inverters and a series of inverters with excellent usability and driving performance.

Transformers

Our transformers help ensure a stable power supply, while improving energy efficiency and disaster preparedness. We have an extensive lineup of transformers, ranging from high voltage to extra-high voltage models.

- The availability of products and services may vary depending on your country or region. For more information, please contact your local distributor.

Inquiries

Contact us for inquiries about our products and quotations.